Learning to drive a manual transmission offers a unique connection to the vehicle‚ and numerous specialists‚ since 2017‚ have aided over 15‚000 individuals!

Many resources‚ including Team ONeil and Stick Shift Specialists‚ provide comprehensive lessons‚ covering everything from basic operation to advanced techniques for confident driving.

Why Learn to Drive a Manual Transmission?

Driving a manual transmission revitalizes the driving experience‚ offering a heightened sense of control and engagement often lost in automatics. Beyond the fun factor‚ mastering a stick shift provides valuable mechanical understanding of how a car functions.

Numerous schools‚ like Stick Shift Specialists‚ emphasize that learning is accessible‚ even with a car provided for practice. It’s a skill that can broaden your driving capabilities and open doors to a wider range of vehicles.

Furthermore‚ understanding manual transmissions can be beneficial for vehicle maintenance and emergency situations‚ offering a deeper connection to the road and your machine.

The Declining Popularity & Resurgence of Manual Cars

While automatic transmissions dominate the current market‚ a surprising resurgence of interest in manual cars is occurring‚ fueled by enthusiasts seeking a more engaging driving experience. Despite declining sales figures over the years‚ dedicated schools like Stick Shift Specialists are thriving‚ teaching over 15‚000 people since 2017.

This revival is driven by a desire to reconnect with the mechanics of driving and appreciate the skill involved.

The availability of focused lessons‚ coupled with the inherent fun of a stick shift‚ is attracting a new generation of drivers to this classic transmission type.

Understanding the Manual Transmission System

Manual transmission systems rely on a clutch‚ gearbox‚ and shift lever working in harmony; lessons emphasize mastering these components for smooth‚ controlled driving.

The Clutch: Its Function and Importance

Clutch control is paramount in manual transmission driving‚ and effective lessons prioritize mastering this skill. The clutch temporarily disconnects the engine from the wheels‚ allowing for gear changes without damaging the drivetrain.

Understanding the “friction point” – where the clutch begins to engage – is crucial for smooth starts and shifts. Instructors at Stick Shift Specialists and Team ONeil focus heavily on this‚ ensuring students develop precise clutch modulation. Improper clutch use‚ like “riding” it‚ leads to premature wear and jerky movements‚ which lessons actively prevent.

Ultimately‚ a well-learned clutch operation is the foundation of enjoyable and efficient manual driving.

Gearbox Basics: How Gears Work

Manual transmission lessons emphasize understanding how gears translate engine power into wheel speed. Different gear ratios provide varying levels of torque and speed; lower gears offer more power for acceleration and hill climbing‚ while higher gears prioritize fuel efficiency at cruising speeds.

Instructors explain how the gearbox utilizes interlocking gears of different sizes to achieve these ratios. Effective lessons‚ like those offered by Stick Shift Specialists‚ demonstrate the relationship between engine RPM‚ gear selection‚ and vehicle speed.

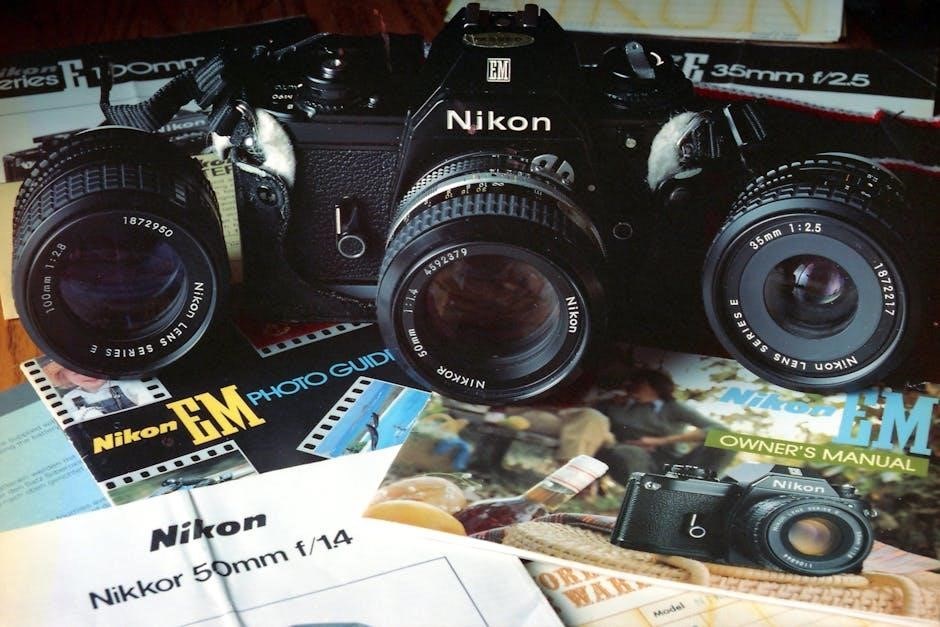

Visual aids‚ such as Engineering Explained videos‚ can reinforce these concepts‚ leading to confident gear selection.

The Shift Lever and Gear Patterns

Manual transmission lessons begin with familiarizing students with the shift lever and its corresponding gear pattern – typically an “H” shape. Instructors at Team ONeil and similar schools guide learners through each gear position‚ emphasizing smooth and accurate movements.

Understanding the gear pattern is crucial for selecting the correct gear for various driving situations.

Effective lessons involve repeated practice in an empty parking lot‚ building muscle memory for precise shifting. Resources like online tutorials visually demonstrate proper lever operation‚ enhancing comprehension and skill development.

Pre-Driving Checks and Preparation

Lessons emphasize adjusting the seat and mirrors for optimal visibility‚ and understanding the pedal layout – clutch‚ brake‚ and gas – is fundamental for success.

Adjusting the Seat and Mirrors

Before starting your manual driving lessons‚ proper seat adjustment is crucial for comfortable and safe operation. Ensure you can fully depress the clutch pedal without straining.

Adjust the seat forward or backward to achieve this‚ and then adjust the seatback angle for good posture. Next‚ meticulously adjust your mirrors – rearview and side mirrors – to minimize blind spots and provide a clear view of your surroundings.

Proper mirror adjustment is paramount for situational awareness during lessons and beyond‚ enhancing overall safety and control while learning to drive a manual transmission.

Understanding the Pedal Layout (Clutch‚ Brake‚ Gas)

For beginners in manual driving lessons‚ mastering the pedal arrangement is fundamental. The leftmost pedal is the clutch‚ used to disengage the engine from the wheels for gear changes.

The middle pedal is the brake‚ functioning identically to automatic vehicles‚ used for slowing or stopping. The rightmost pedal is the accelerator (gas)‚ controlling engine speed and power.

During lessons‚ focus on smooth‚ coordinated movements between these pedals‚ especially the clutch and gas‚ to avoid stalling and achieve seamless gear shifts. Practice identifying each pedal quickly and accurately.

Starting the Engine: A Step-by-Step Guide

During manual driving lessons‚ starting the engine requires a specific sequence. First‚ ensure the gear lever is in neutral. Fully depress the clutch pedal – this disengages the engine.

Turn the ignition key to start the engine. Once running‚ maintain pressure on the clutch. Gradually release the clutch while gently pressing the accelerator.

This coordinated action prevents stalling. Instructors emphasize finding the “friction point” – where the engine begins to engage – for a smooth start. Practice this repeatedly for muscle memory.

Mastering the Basics of Gear Shifting

Manual driving lessons focus on coordinating clutch and shifter movements‚ finding the friction point‚ and executing smooth upshifts and downshifts for optimal control.

Finding the Friction Point

Identifying the friction point is crucial when learning a manual transmission; it’s the sweet spot where the clutch begins to engage the engine‚ allowing power transfer.

Lessons emphasize slowly releasing the clutch while gently applying gas‚ listening for a slight engine note change and feeling the car begin to move forward.

Instructors guide students to avoid simply “dumping” the clutch‚ which causes stalling‚ and instead focus on controlled engagement. Mastering this point enables smooth starts and prevents jerky movements‚ forming the foundation for confident driving.

Practice in an empty lot helps build muscle memory and refine this essential skill.

Smooth Starting from a Stop

Successfully starting from a stop with a manual transmission requires coordinating the clutch‚ gas‚ and handbrake. Lessons begin with finding the friction point‚ then gently increasing gas as the clutch is released further.

Instructors emphasize avoiding stalling by maintaining a balance between engine speed and clutch engagement. Using the handbrake on inclines prevents rollback‚ allowing focus on clutch and gas control.

Practice builds muscle memory‚ leading to seamless starts without jerking or hesitation. Mastering this skill is fundamental for confident and controlled driving.

Upshifting: Moving to Higher Gears

Upshifting‚ transitioning to a higher gear‚ is crucial for efficient driving and maintaining optimal engine speed. Lessons focus on smoothly releasing the gas pedal while simultaneously depressing the clutch and moving the shift lever.

Instructors teach coordinating these actions to minimize power loss and ensure a seamless transition. The goal is to match engine speed to the new gear‚ avoiding abrupt shifts or engine strain.

Consistent practice refines timing and technique‚ resulting in fluid upshifts that enhance the driving experience and improve fuel economy.

Downshifting: Reducing Speed and Increasing Power

Downshifting involves selecting a lower gear‚ effectively increasing engine RPM and providing greater control‚ especially when approaching corners or needing more acceleration. Driving lessons emphasize the importance of rev-matching during downshifts.

Rev-matching‚ briefly increasing engine speed with the gas pedal before releasing the clutch‚ creates a smoother transition and reduces wear on the clutch. Instructors guide students through this technique.

Mastering downshifting enhances control‚ improves responsiveness‚ and allows for more confident and engaging driving experiences.

Advanced Driving Techniques

Lessons progress to hill starts‚ smooth gear changes at speed‚ and rev-matching—skills that elevate control and confidence for experienced manual driving.

Hill Starts: Preventing Rollback

Hill starts can be daunting for new manual drivers‚ but mastering the technique is crucial for confident driving. Lessons emphasize coordinating the clutch‚ gas‚ and handbrake to prevent rollback.

Instructors at Stick Shift Specialists and Team ONeil teach a controlled method: engage the handbrake‚ find the friction point‚ gently apply gas‚ and smoothly release the handbrake as you increase pressure on the accelerator.

This prevents unwanted movement and allows for a seamless transition from a stop to an uphill climb. Practice is key to developing muscle memory and achieving smooth‚ rollback-free hill starts.

Smooth Gear Changes at Speed

Lessons focusing on gear changes at speed aim to eliminate jerkiness and maintain vehicle momentum. Instructors highlight the importance of timing and clutch control for seamless transitions.

Techniques taught by specialists like those at Stick Shift Specialists involve briefly depressing the clutch‚ swiftly moving the shift lever to the desired gear‚ and smoothly releasing the clutch while simultaneously applying appropriate gas.

Engineering Explained’s visual guides reinforce these concepts‚ demonstrating how synchronized movements create a fluid driving experience‚ enhancing both comfort and efficiency.

Rev Matching for Smoother Downshifts

Manual transmission lessons often include rev matching‚ a technique to synchronize engine speed with the lower gear before releasing the clutch during downshifts. This minimizes jolts and wear on the clutch.

Instructors at Team ONeil emphasize briefly “blipping” the throttle while the clutch is disengaged‚ raising the engine RPM to match the wheel speed of the lower gear.

Resources like Engineering Explained visually demonstrate this process‚ explaining how it creates a smoother‚ more controlled driving experience‚ and ultimately extends the life of your vehicle’s components.

Common Mistakes and How to Avoid Them

Manual driving lessons address frequent errors like stalling‚ jerky shifts‚ and “riding the clutch‚” emphasizing smooth coordination and proper pedal control for success.

Stalling the Engine

Stalling is a common frustration for new manual transmission learners‚ often stemming from insufficient gas while releasing the clutch‚ or releasing the clutch too quickly. Driving lessons emphasize finding the “friction point” – the sweet spot where the clutch begins to engage – and coordinating gas pedal input with clutch release.

Instructors at Stick Shift Specialists and Team ONeil focus on building muscle memory through repetitive practice in a safe environment. Avoiding abrupt clutch movements and maintaining consistent gas pressure are key. Remember‚ a gentle touch and smooth coordination are vital to prevent the engine from cutting out‚ building confidence with each successful start and shift.

Jerky Shifts

Jerky shifts indicate a mismatch between engine speed and gear selection‚ often caused by improper clutch engagement or insufficient throttle control during gear changes. Manual transmission driving lessons‚ like those offered by Stick Shift Specialists‚ prioritize smooth transitions between gears.

Instructors teach techniques like rev-matching – briefly increasing engine RPMs to synchronize with the next gear – to minimize jolts. Consistent practice in an open area helps develop the coordination needed for seamless upshifts and downshifts. Focus on a fluid clutch release and precise throttle adjustments for a comfortable ride.

Riding the Clutch

Riding the clutch – partially depressing the pedal during driving – causes excessive wear and tear on the clutch disc and release bearing. Comprehensive manual transmission driving lessons‚ such as those provided by Team ONeil‚ emphasize complete clutch engagement or disengagement.

Instructors demonstrate how to fully release the pedal after shifting and avoid using it as a makeshift brake or to maintain speed on inclines. This practice extends clutch life and promotes efficient driving. Proper technique‚ reinforced through practice‚ prevents premature component failure.

Practice Exercises for Skill Development

Lessons incorporate empty parking lot drills‚ residential street practice‚ and highway driving to build confidence and refine skills in a safe‚ progressive manner.

Empty Parking Lot Drills

Parking lots provide an ideal‚ controlled environment for initial practice with a manual transmission. Focus on mastering smooth starts and stops‚ repeatedly engaging and disengaging the clutch and shifting between first and second gear.

Instructors at Stick Shift Specialists utilize open practice areas for this very purpose‚ emphasizing clutch control and finding the friction point. Practice gentle acceleration and deceleration‚ aiming for seamless gear changes without stalling.

These drills build muscle memory and coordination‚ essential for confident driving in more complex situations. Gradually increase speed as comfort levels grow‚ always prioritizing smooth operation.

Residential Street Practice

Transitioning to residential streets introduces real-world variables like traffic signals and varying speeds. Continue practicing smooth starts and stops‚ focusing on timely gear changes to maintain control and momentum.

Anticipate traffic flow and utilize appropriate gears for efficient driving. Practice upshifting and downshifting while maintaining a safe following distance. Remember the lessons on clutch control from specialists like Stick Shift Specialists.

Pay close attention to surroundings and practice defensive driving techniques. This phase builds confidence and prepares you for more challenging road conditions.

Highway Driving Practice

Highway driving demands sustained speed and efficient gear selection. Practice maintaining a consistent speed in higher gears‚ utilizing smooth upshifts and downshifts for passing or merging.

Focus on anticipating traffic conditions and maintaining a safe following distance. Utilize the techniques learned from resources like Engineering Explained for optimal gear ratios. Remember to practice rev-matching for smoother transitions.

This stage builds confidence in high-speed control and reinforces the skills acquired during earlier practice sessions‚ preparing you for long-distance driving.

Parallel Parking with a Manual Transmission

Mastering parallel parking with a manual requires precise clutch control and coordination; specialists offer step-by-step guidance to overcome common challenges effectively.

Practice troubleshooting issues and refine your technique for confident maneuvering in tight spaces.

Step-by-Step Guide to Manual Parallel Parking

Initiate by signaling and aligning your vehicle alongside the target parking space‚ maintaining about two to three feet of distance. Gently reverse‚ checking mirrors frequently‚ until your rear bumper aligns with the other vehicle’s rear bumper.

Steer sharply towards the curb while continuing to reverse slowly‚ utilizing clutch control to maintain a steady pace. Monitor your surroundings carefully‚ adjusting steering as needed to avoid contact. Once angled sufficiently‚ straighten the wheel and continue reversing until fully parked.

Finally‚ shift into drive and adjust your position if necessary‚ ensuring you are within six inches of the curb. Remember‚ practice with a qualified instructor builds confidence!

Troubleshooting Common Parallel Parking Issues

Stalling is frequent; maintain consistent clutch control and gentle throttle application. Jerky movements indicate poor coordination – practice smooth steering and clutch engagement. If too far from the curb‚ re-attempt the maneuver‚ adjusting the initial angle.

Hitting the curb suggests oversteering; reduce steering angle and proceed slower. Difficulty judging distances requires focused mirror checks and spatial awareness. Remember‚ patience is key!

Professional lessons from Stick Shift Specialists or Team ONeil can pinpoint individual challenges and provide tailored solutions for mastering this skill with a manual transmission.

Resources for Further Learning

Engineering Explained and Learn to Drive with Confidence offer excellent video tutorials‚ while NHTSA provides free driving manuals for enhanced learning!

Stick Shift Specialists and Team ONeil deliver professional‚ hands-on lessons to refine your manual transmission skills.

Online Video Tutorials (Engineering Explained‚ Learn to Drive with Confidence)

Leveraging online video tutorials is a fantastic way to supplement practical manual transmission lessons; Channels like Engineering Explained meticulously dissect the mechanics of clutch control and gear shifting‚ providing a deep understanding of the system’s inner workings.

Learn to Drive with Confidence offers visually engaging guides that reinforce concepts learned during hands-on practice‚ specifically focusing on crucial maneuvers like hill starts and smooth gear changes. These resources are invaluable for visualizing the coordination required for successful driving‚ and can dramatically accelerate your learning curve. They provide a convenient and accessible way to review techniques and troubleshoot common challenges.

NHTSA Driving Manuals

Complementing practical manual transmission lessons with resources from the U.S. Department of Transportation’s National Highway Traffic Safety Administration (NHTSA) is highly recommended. NHTSA provides free‚ downloadable driving manuals that cover safe driving practices‚ including dedicated sections on operating a manual gearbox.

These manuals offer a comprehensive overview of vehicle control‚ traffic laws‚ and defensive driving techniques‚ specifically addressing the nuances of a standard transmission. Utilizing these official guides ensures a solid foundation in both the mechanical aspects and the legal requirements for safe and responsible driving.

Professional Driving Schools (Stick Shift Specialists‚ Team ONeil)

For dedicated instruction‚ consider professional driving schools like Stick Shift Specialists and Team ONeil. Since 2017‚ Stick Shift Specialists have helped over 15‚000 people master manual transmission‚ offering car-inclusive lessons in open practice areas with a complete curriculum.

Team ONeil provides two-hour lessons focused on the basics‚ ensuring comfort and safety in a spacious environment. These schools offer structured learning‚ expert guidance‚ and a focused approach to building confidence behind the wheel of a stick-shift vehicle.

Maintaining Your Manual Transmission Vehicle

Regular maintenance‚ including clutch checks and gearbox fluid changes‚ is crucial for longevity. Proper care ensures smooth operation and enhances the driving experience!

Clutch Maintenance and Replacement

The clutch is a vital component‚ experiencing significant wear during manual transmission driving. Regular inspection is key; listen for unusual noises like squealing or grinding‚ indicating potential issues. Check the clutch fluid level and look for leaks.

“Riding the clutch‚” a common mistake during lessons‚ accelerates wear. Eventually‚ replacement becomes necessary. Costs vary based on vehicle and labor‚ but proactive maintenance can delay this. Signs of a failing clutch include slipping gears‚ difficulty shifting‚ and a high pedal position. Professional inspection is recommended for accurate diagnosis and repair.

Gearbox Fluid Checks and Changes

Maintaining proper gearbox fluid levels is crucial for smooth manual transmission operation‚ a key element emphasized in driving lessons. Regularly check the fluid level using the dipstick – consult your vehicle’s manual for the correct procedure. Look for a bright‚ clear fluid; dark or gritty fluid indicates contamination.

Fluid changes are essential‚ typically every 30‚000-60‚000 miles‚ depending on driving conditions. Using the correct fluid type is vital; incorrect fluid can cause damage. Proper fluid levels ensure efficient gear changes and prolong the life of the gearbox‚ enhancing the overall driving experience.

Safety Considerations for Manual Driving

Manual driving lessons stress defensive techniques and situational awareness; being alert enhances control and prevents accidents‚ ensuring a safer‚ more confident driving experience.

Defensive Driving Techniques

Manual driving lessons heavily emphasize defensive strategies‚ going beyond basic operation. Instructors at places like Stick Shift Specialists and Team ONeil teach anticipating potential hazards and reacting proactively. This includes maintaining a safe following distance‚ scanning mirrors frequently‚ and being aware of surrounding vehicles.

Understanding how the manual transmission impacts vehicle response is crucial; quick downshifts for emergency braking or anticipating traffic flow require practice. Lessons focus on smooth‚ controlled maneuvers‚ minimizing reaction time and maximizing safety in unpredictable situations. Ultimately‚ defensive driving with a manual builds confidence and reduces risk.

Being Aware of Your Surroundings

Manual driving lessons prioritize heightened situational awareness‚ a critical component of safe operation. Instructors stress constant scanning – mirrors‚ blind spots‚ and the road ahead – to anticipate potential hazards. This differs from automatic driving‚ demanding more driver engagement.

Lessons from specialists like Stick Shift Specialists and Team ONeil emphasize recognizing traffic patterns‚ pedestrian movements‚ and potential obstacles. Mastering clutch control and gear selection allows quicker responses to changing conditions. A focused driver‚ fully aware of their environment‚ is a safer driver‚ especially with a manual transmission.