Aroma 6-Cup Rice Cooker: A Comprehensive Instruction Manual Guide

This manual details safe operation, cooking rice, steaming, slow cooking, and maintenance. It covers features like the steam tray, keep-warm function, and troubleshooting common issues.

Understanding Your Aroma Rice Cooker

Your Aroma 6-Cup Rice Cooker is a versatile kitchen appliance designed for simple and efficient cooking. Beyond basic rice preparation, it functions as a slow cooker and steamer, offering diverse culinary possibilities. This model, often referenced in manuals dated 2024 and 2025, prioritizes user-friendliness with intuitive controls for cooking and warming.

Understanding its capabilities – from low-temperature cooking to quick defrosting – unlocks its full potential. The cooker’s power levels (600W, 800W) cater to various tasks, including gentle heating for baby food or robust cooking for vegetables. Familiarizing yourself with these features, as outlined in the RC-5MSIH manual, ensures optimal performance and extends the appliance’s lifespan. Proper usage, guided by this manual, guarantees delicious results every time.

Key Components and Their Functions

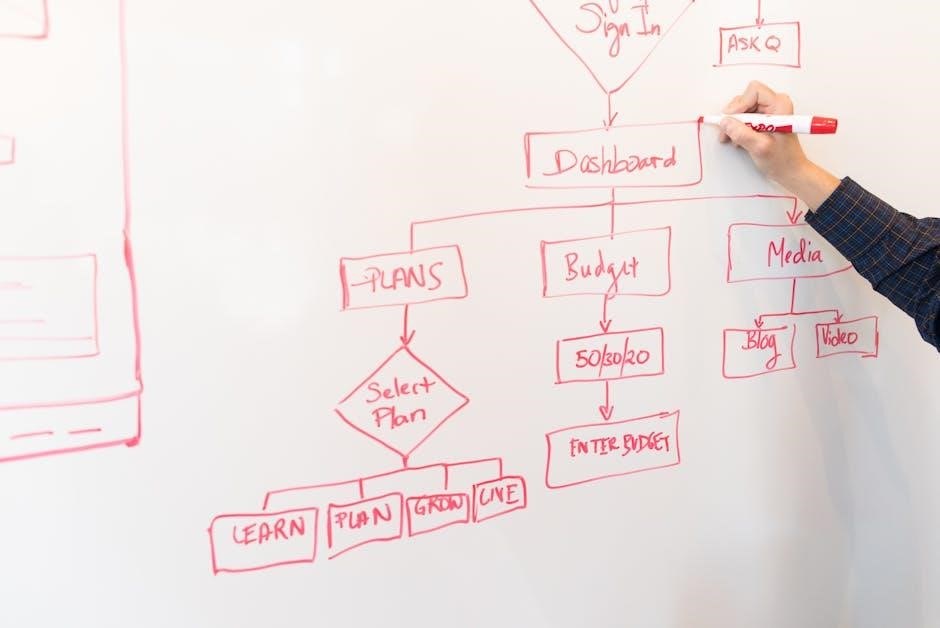

The Aroma 6-Cup Rice Cooker comprises several essential parts. These include the rice/soup cooking bowl (4), crucial for all cooking processes, and the steam tray (6), enabling simultaneous vegetable or fish steaming. Steam cups (1, 2, or 3) support the cooking bowl within the unit.

The cooker features distinct power settings – 360W for melting or gentle warming, 600W for low-temperature cooking and rice boiling, and 800W for faster cooking of vegetables. Understanding these settings, detailed in the instruction manual, is vital. The cook/warm switch controls cooking cycles, while the steam button activates steaming functions. Proper component identification, as shown in diagrams within the manual, ensures correct assembly and operation for optimal results.

Safety Precautions Before First Use

Prior to initial operation, carefully review all safety guidelines. The instruction manual emphasizes 17 crucial precautions to minimize risks. Always ensure the cooker is placed on a stable, heat-resistant surface with adequate ventilation. Never immerse the appliance, cord, or plug in water.

Avoid operating the cooker with a damaged cord or plug. Do not use outdoors. Keep the cooker away from flammable materials. Supervise children when the appliance is in use. Allow the cooker to cool completely before cleaning. Disconnect from the power outlet when not in use and before cleaning; Following these safeguards ensures safe and reliable operation, protecting both users and the appliance.

Getting Started: Initial Setup

Unbox, inspect components, and clean before first use. Proper placement with ventilation is key for optimal performance and longevity of your Aroma cooker.

Unboxing and Inspecting the Contents

Carefully remove your Aroma 6-Cup Rice Cooker from its packaging. Ensure all components are present: the rice cooker base, inner cooking bowl, steam tray (1, 2, or 3 depending on model), measuring cup, and serving spatula.

Thoroughly inspect each item for any signs of damage incurred during shipping. Check the inner bowl for dents or scratches, and the cooker base for cracks or loose parts. Verify the power cord is intact and free from fraying;

Compare the contents against the parts list included in this manual. If any items are missing or damaged, immediately contact Aroma customer support for assistance and replacement parts. Retain all packaging materials until you’ve confirmed all components are in good working order. This ensures a smooth start to enjoying your new rice cooker!

Cleaning the Rice Cooker Before First Use

Before your initial use, a thorough cleaning is essential. Remove the inner cooking bowl and steam tray. Wash both with warm, soapy water, ensuring all manufacturing residues are eliminated. Rinse completely and dry thoroughly before reassembling.

Wipe the exterior of the rice cooker base with a damp cloth. Avoid using abrasive cleaners, as they may damage the finish. Never immerse the base in water or any other liquid. Ensure the heating plate inside the cooker is dry before proceeding.

This initial cleaning process removes any potential odors or particles left from the manufacturing process, guaranteeing a fresh start for your cooking endeavors. Proper cleaning contributes to the longevity and performance of your Aroma rice cooker.

Proper Placement and Ventilation

For optimal performance and safety, place your Aroma rice cooker on a stable, level surface. Ensure there is adequate ventilation around the unit – at least four inches of free space on all sides is recommended. Avoid placing it near flammable materials, curtains, or anything heat-sensitive.

Do not operate the rice cooker on a soft surface like a carpet or tablecloth, as this can obstruct airflow and potentially cause overheating. Keep the ventilation openings clear of dust and debris.

Proper placement prevents potential hazards and ensures efficient operation. Avoid direct sunlight and moisture exposure. Following these guidelines will maximize the lifespan and functionality of your Aroma 6-cup rice cooker.

Cooking Rice: The Basics

Mastering rice cooking involves precise water ratios and utilizing the cook/warm settings. This section provides step-by-step instructions for fluffy, perfect rice every time.

Rice to Water Ratio Guide

Achieving perfectly cooked rice hinges on the correct rice-to-water ratio. For white rice, a standard guideline is 1 cup of rice to 1.5 cups of water. However, adjustments are often necessary based on rice type and desired texture. Brown rice typically requires a higher water ratio, around 1 cup of rice to 2 cups of water, and a longer cooking time.

Jasmine and Basmati rice varieties often benefit from slightly less water – approximately 1 cup of rice to 1.25 cups of water – to maintain their distinct fragrance and fluffy consistency. Experimentation is key to finding the ideal ratio for your preferences. Remember to always use the measuring cup provided with your Aroma rice cooker for consistent results. Accurate measurements are crucial for preventing burning or undercooked rice.

Step-by-Step Rice Cooking Instructions

Begin by measuring the desired amount of rice and rinsing it thoroughly under cold water until the water runs clear. This removes excess starch, preventing stickiness. Add the rinsed rice to the cooking bowl and pour in the appropriate amount of water, referencing the rice-to-water ratio guide.

Place the cooking bowl inside the rice cooker, ensuring it sits securely on the steam tray (if using). Close the lid tightly and select the “Cook” setting. The cooker will automatically switch to the “Warm” setting once the rice is cooked. Allow the rice to steam for 10-15 minutes with the lid closed before fluffing with a fork. Enjoy your perfectly cooked rice!

Using the Cook/Warm Settings

The “Cook” setting initiates the cooking cycle, bringing the water to a boil and then simmering the rice until all the moisture is absorbed. Once completed, the rice cooker automatically transitions to the “Warm” setting. This maintains the rice at an ideal serving temperature without overcooking it.

The “Warm” setting is designed for extended holding periods, keeping rice palatable for hours. However, prolonged warming can slightly dry out the rice. For optimal texture, it’s recommended to consume the rice within a few hours of cooking. Avoid leaving cooked rice on the “Warm” setting overnight to prevent bacterial growth. Remember to unplug the cooker when not in use.

Advanced Cooking Features

Explore versatile options beyond basic rice cooking! Utilize the steam tray for vegetables, enjoy slow cooking recipes, and leverage the convenient keep-warm function.

Steam Tray Usage for Vegetables & More

The Aroma 6-Cup Rice Cooker’s steam function expands its culinary capabilities. Simply place one to three steam cups onto the tray (6), then position the rice/soup cooking bowl (4) atop them. This creates a tiered cooking system, ideal for simultaneously preparing a complete meal.

Add your desired vegetables – broccoli, carrots, or green beans work wonderfully – to the steam cups. Ensure they are cut into appropriately sized pieces for even steaming. As the rice cooks below, the steam rises and gently cooks the vegetables above, preserving their nutrients and flavor. This method isn’t limited to vegetables; you can also steam fish or dumplings for a healthy and convenient meal. Remember to check for doneness periodically, adjusting steaming time as needed based on the food type and quantity.

Slow Cooking Function: Recipes & Tips

The Aroma 6-Cup Rice Cooker offers a convenient slow cooking function for flavorful, tender meals. This feature allows for extended, low-temperature cooking, perfect for soups, stews, and braised dishes. Begin by sautéing ingredients directly in the cooker pot using the cook setting before switching to slow cook.

For a hearty beef stew, brown cubed beef, then add vegetables like carrots, potatoes, and onions. Pour in broth and seasonings, then select the slow cook setting. Cooking times vary depending on the recipe, but typically range from 2-6 hours. Remember to use lower liquid levels than traditional slow cookers, as minimal evaporation occurs; Experiment with recipes – chili, pulled pork, and even oatmeal are excellent choices! Always ensure ingredients are fully cooked before serving.

Keep Warm Function: Duration & Best Practices

The Aroma 6-Cup Rice Cooker’s “Keep Warm” function automatically activates after cooking completes, maintaining rice at an ideal serving temperature. This feature can safely hold rice warm for up to 12 hours, though quality may slightly diminish over extended periods. For optimal texture, it’s best to consume rice within the first few hours.

Avoid leaving rice on “Keep Warm” for more than 24 hours, as this can encourage bacterial growth. To prevent sticking, occasionally fluff the rice with a fork during the warm cycle. If using the keep warm function for other foods, monitor closely and adjust duration accordingly. Remember, the keep warm setting uses minimal energy, but isn’t intended for reheating cold food.

Cleaning and Maintenance

Regular cleaning ensures longevity and performance. Daily procedures involve washing the bowl and steam tray; deep cleaning requires a thorough wipe-down of the cooker’s exterior.

Daily Cleaning Procedures

After each use, unplug the Aroma rice cooker and allow it to cool completely before beginning the cleaning process. Remove the inner cooking bowl and thoroughly wash it with warm, soapy water. A non-abrasive sponge or cloth is recommended to prevent scratching the non-stick coating. Rinse the bowl completely and dry it before storing.

The steam tray should also be washed after each use, following the same procedure as the inner bowl. Ensure all food residue is removed. Wipe the exterior of the rice cooker with a damp cloth to remove any spills or splatters. Avoid immersing the main unit in water or any other liquid. Regularly inspect the heating plate for any buildup and gently wipe clean with a damp cloth if necessary. Proper daily cleaning will maintain optimal performance and hygiene.

Deep Cleaning Instructions

For a more thorough clean, perform a deep cleaning monthly, or as needed. After unplugging and cooling, remove all detachable parts – the inner pot, steam tray, and lid. Wash these components with warm, soapy water, paying close attention to any stubborn food residue. For baked-on food, soak the parts in warm water for 30 minutes before washing.

Inspect the sealing ring on the lid and gently clean it to remove any buildup. Avoid harsh chemicals or abrasive cleaners, as they can damage the components. Wipe down the exterior of the cooker with a slightly damp cloth. Ensure all parts are completely dry before reassembling. This deep cleaning process helps maintain the cooker’s longevity and prevents odors or bacterial growth, ensuring consistently delicious results.

Troubleshooting Common Issues (Burning, Uneven Cooking)

If rice burns, reduce the water ratio slightly in future attempts. Ensure the inner pot is clean and free of residue before cooking. For uneven cooking, verify the rice is evenly distributed within the pot. Stirring gently after adding water can help. If the cooker won’t turn on, check the power cord and outlet.

A faulty heating element may require professional repair. If steam isn’t releasing, ensure the steam vent isn’t blocked. Avoid overfilling the cooker, as this can cause overflow and uneven cooking. Regularly cleaning the cooker prevents buildup that can contribute to these issues. Consistent use of the correct rice-to-water ratio is crucial for optimal performance.

Specific Rice Types & Cooking Adjustments

Adjust water levels for different rice varieties—white, brown, jasmine, and basmati— to achieve perfectly cooked results every time with your Aroma cooker.

Cooking White Rice Perfectly

Achieving fluffy, perfectly cooked white rice is simple with your Aroma 6-Cup Rice Cooker. Begin by thoroughly rinsing the rice under cold water until the water runs clear, removing excess starch. A standard ratio is 1 cup of white rice to 1.5 cups of water, though slight adjustments may be needed based on rice grain length.

Place the rinsed rice and water into the cooking bowl. Securely close the lid, ensuring proper steam release. Press the “Cook” button. The cooker will automatically switch to “Warm” once cooking is complete—typically around 30 minutes. Allow the rice to rest, covered, for 10-15 minutes before fluffing with a fork. This resting period allows steam to redistribute, resulting in even more tender rice. Experiment with minor water adjustments to find your preferred consistency.

Brown Rice Cooking Guide

Cooking brown rice in your Aroma cooker requires a slightly different approach than white rice due to its bran layer. Begin by rinsing the brown rice to remove any debris. A typical ratio is 1 cup of brown rice to 2.25-2.5 cups of water; more water is needed for brown rice as it takes longer to cook.

Place the rinsed rice and water into the cooking bowl and secure the lid. Press the “Cook” button. Brown rice generally takes 45-50 minutes to cook. Once switched to “Warm,” allow the rice to steam, covered, for 10 minutes before fluffing. If the rice is still too firm, add a tablespoon or two of water and cook for another 5-10 minutes. Adjust water levels in future attempts to achieve your desired texture.

Jasmine & Basmati Rice: Optimal Settings

Jasmine and Basmati rice, known for their fragrant aromas and delicate textures, require specific water ratios for optimal results in your Aroma cooker. For Jasmine rice, use a ratio of 1 cup of rice to 1.25 cups of water. Basmati rice typically needs slightly less, around 1 cup of rice to 1.125-1.2 cups of water.

Rinse the rice gently before cooking to remove excess starch. Select the “White Rice” setting on your cooker. The cooking time will be similar to white rice, approximately 20-25 minutes. After the cycle completes and switches to “Warm,” let the rice rest, covered, for 10 minutes. Fluff gently with a fork before serving to separate the grains and enhance the aroma.

Using the Rice Cooker for Other Foods

Beyond rice, this versatile cooker excels at soups, stews, steamed vegetables, fish, and even desserts like rice pudding—expanding your culinary options.

Cooking Soups and Stews

The Aroma rice cooker isn’t limited to rice; it’s surprisingly adept at preparing flavorful soups and hearty stews. Begin by sautéing vegetables directly in the cooker using the appropriate power level (600W or 800W, depending on your model) before adding liquids and proteins.

Ensure sufficient liquid is present to prevent burning, and adjust cooking times based on the recipe. Utilize the ‘Slow Cook’ function for extended simmering, allowing flavors to meld beautifully. Remember to monitor the cooker periodically, especially during longer cooking durations. The keep-warm function is ideal for maintaining serving temperature after the soup or stew is ready. Always follow standard food safety guidelines when cooking meats and poultry.

Steaming Vegetables and Fish

Leverage the included steam tray to effortlessly steam vegetables and delicate fish alongside your rice. Add water to the main cooking bowl – typically 1 cup – and place the steam tray securely inside. Arrange your chosen vegetables or fish on the tray, ensuring they aren’t overcrowded for even steaming.

Select the appropriate cooking setting; the regular ‘Cook’ cycle often suffices. Steaming times vary depending on the vegetable or fish type; check for doneness periodically. The steam function preserves nutrients and delivers tender, flavorful results. Avoid overfilling the steam tray, and consider adding seasonings directly to the food for enhanced taste.

Making Rice Pudding & Desserts

Your Aroma rice cooker isn’t limited to savory dishes; it excels at creating creamy rice pudding and other delightful desserts! Begin with cooked rice – leftover rice works perfectly. Combine the rice with milk, sugar, and your preferred flavorings (vanilla, cinnamon, fruit) directly in the cooking bowl.

Utilize the ‘Cook’ setting initially, then switch to ‘Warm’ to gently simmer and thicken the pudding to your desired consistency, stirring occasionally to prevent sticking. For other desserts, adapt recipes designed for stovetop cooking, adjusting liquid levels as needed. You can enjoy rice pudding warm or chilled, garnished with almonds or pistachios for added texture and flavor.

Troubleshooting & FAQs

Common issues like the cooker not turning on, burning, or a malfunctioning steam button are addressed. Solutions and frequently asked questions are provided for optimal use.

Rice Cooker Won’t Turn On

If your Aroma rice cooker fails to power on, begin with the basics. First, ensure the power cord is securely plugged into both the cooker and a functioning wall outlet. Test the outlet with another appliance to confirm it’s providing power.

Next, verify the cooker’s lid is properly sealed. Many models feature a safety mechanism preventing operation if the lid isn’t fully closed. Check for any obstructions or debris around the power button or control panel. If the issue persists, inspect the power cord for any visible damage, such as cuts or fraying.

A faulty power cord may require replacement. As a final step, consult the warranty information to determine if the unit is still covered for repair or replacement. Do not attempt to disassemble or repair the cooker yourself, as this could void the warranty and pose a safety hazard.

Rice is Burning or Sticking

Experiencing burnt or sticky rice is a common issue, often stemming from incorrect rice-to-water ratios. Always adhere to the recommended ratios for your specific rice type – white, brown, jasmine, or basmati. Ensure the inner pot is thoroughly cleaned before each use, removing any residual starch buildup. A buildup can contribute to sticking.

Consider reducing the cooking time slightly, especially for smaller rice quantities. Also, avoid overfilling the cooker, as this can lead to uneven cooking and potential burning. If using the “Keep Warm” function for extended periods, be aware that it can dry out the rice, causing it to stick.

Regularly inspect the heating element for any signs of damage or buildup. A damaged element may cause uneven heating. If burning persists despite these measures, try lightly greasing the inner pot with cooking oil before adding rice.

Steam Button Not Working

If the steam button fails to activate, first ensure the unit is properly plugged in and receiving power. Check the power outlet with another device to confirm functionality. Verify that the steam tray is correctly positioned within the cooker; it must be securely seated for the steam function to operate.

Inspect the steam vent for any blockages. Food particles or mineral deposits can obstruct steam flow, preventing the button from working. Gently clean the vent with a damp cloth or a small brush. Ensure there’s sufficient water in the cooker; the steam function requires adequate liquid to generate steam.

If the issue persists, try resetting the cooker by unplugging it for several minutes and then plugging it back in. If none of these steps resolve the problem, contact Aroma customer support for further assistance.

Warranty Information & Support

Aroma offers a warranty on its rice cookers; details are included within. Contact customer support for assistance or to find replacement parts if needed.

Aroma Rice Cooker Warranty Details

Aroma diligently stands behind the quality of its 6-Cup Rice Cookers, offering a limited warranty to ensure customer satisfaction. This warranty typically covers defects in materials and workmanship under normal household use for a specified period, generally one year from the date of original purchase.

The warranty does not cover damage resulting from misuse, accidents, unauthorized repairs, or normal wear and tear. To make a warranty claim, retain your proof of purchase and contact Aroma Customer Support with details of the issue. Aroma reserves the right to repair or replace the defective product, or issue a refund, at their discretion.

Please note that this is a general overview; specific warranty terms and conditions may vary depending on the model and region. Refer to the separate warranty card included with your rice cooker for complete details.

Contacting Customer Support

Aroma provides multiple avenues for customers needing assistance with their 6-Cup Rice Cooker. For immediate support, visit the official Aroma website – often featuring a comprehensive FAQ section and troubleshooting guides. You can typically find a “Contact Us” page with direct links to support resources.

Alternatively, Aroma offers customer support via email and phone. Email responses generally take 24-48 hours, while phone support provides real-time assistance during business hours. When contacting support, have your model number and proof of purchase readily available to expedite the process.

Detailed contact information, including phone numbers and email addresses, can be found within your product’s instruction manual or on the Aroma website’s support section. They are dedicated to resolving any issues you may encounter.

Finding Replacement Parts

Maintaining your Aroma 6-Cup Rice Cooker is easy with readily available replacement parts. The official Aroma website is the primary source for genuine components, including inner pots, steam trays, lids, and measuring cups. You can search by model number to ensure compatibility.

Several online retailers also stock Aroma replacement parts, offering competitive pricing and convenient shipping options. Before purchasing from third-party sellers, verify the authenticity of the parts to guarantee quality and performance. Always prioritize genuine Aroma components for optimal functionality.

If you encounter difficulty locating a specific part, contact Aroma customer support directly. They can assist with identifying the correct part number and provide information on authorized distributors. Proper part replacement extends the lifespan of your rice cooker.